Food unwrapped: How blue cheese is really made – ‘fascinating’ process takes 12 weeks

08/23/2021Food Unwrapped: Andrea Oliver learns how blue cheese is made

We use your sign-up to provide content in ways you’ve consented to and to improve our understanding of you. This may include adverts from us and 3rd parties based on our understanding. You can unsubscribe at any time. More info

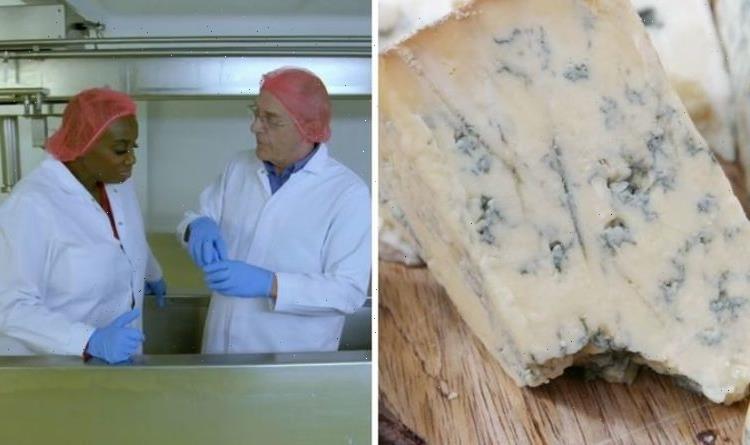

Food Unwrapped goes behind the scenes of several production lines to find out exactly how food items are made. On tonight’s episode of Food Unwrapped on Channel 4, viewers found out just exactly how blue cheese is made.

Blue cheese is one of the most popular cheeses in the world despite its distinctive flavour and smell.

Known for its strong smell, blue cheese is made from cow, goat or sheep’s milk.

It forms its blue veins through being cured with cultured from the mould Penicillium.

On tonight’s episode of Food Unwrapped, presenter Andrea Oliver found out exactly how mould gets into blue cheese.

She said: “Blue cheese, luckily this isn’t smell-o-vision.

“Whether you’re a fromage fanatic or an amateur cheddar head, there’s no denying that the near mention of a stinky blue divides opinion.

“But for those of us who think blue cheese is the bees knees, there’s something I want to know.

“I’m trying to find out how they get the mould inside my blue cheese.”

DON’T MISS:

Daily horoscope for August 23: Your star sign reading [INSIGHT]

Spanish town tells people to leave if they ‘can’t handle’ rural life [COMMENT]

Michael Mosley shares best time of the day to eat for weight loss [EXPERT]

Andrea visited Derbyshire where she found out exactly how the cheese was made at Hartington Creamery in Matlock.

Meeting Alan Salt, the presenter said: “I’ve arrived just as the new batch of stilton is starting life.

“It’s a British institution we’ve been making for more than 300 years.”

Alan said: “This batch of curd will make about one tonne of cheese.

“This is what is going to go in, it’s the Penicillium roqueforti.”

The fungus is a mould culture that will grow to give the cheese its “blue vein” like appearance.

Although Alan’s recipe is top secret, presenter Andrea did get a sneak peak into the lengthy process.

The curd is drained overnight and then ground into small pieces, before being gathered up into plastic cylinders.

The cheese is not pressed like cheddar which leaves small air pockets within the cheese.

These air pockets are where the mould will grow after some time of being left.

Presenter Andrea said: “The next stage is called sealing the cheese, this stops oxygen getting in which the mould needs to grow.”

Once sealed, the cheese is then moved to a special room where it ripens for 12 weeks before the last stage.

Little holes are made in the cheese, helping the oxygen into the food which enables the mould to grow.

Twitter users were amazed with the process, with one person tweeting: “This is fascinating, I didn’t even think that is how it was made!”

Another said: “Food Unwrapped showing how the cheese is made, looks quite processed.”

“No wonder blue cheese is quite expensive, it takes so long to make,” commented a third.

Source: Read Full Article